Hanna Direct System Injection for Tunnel Systems

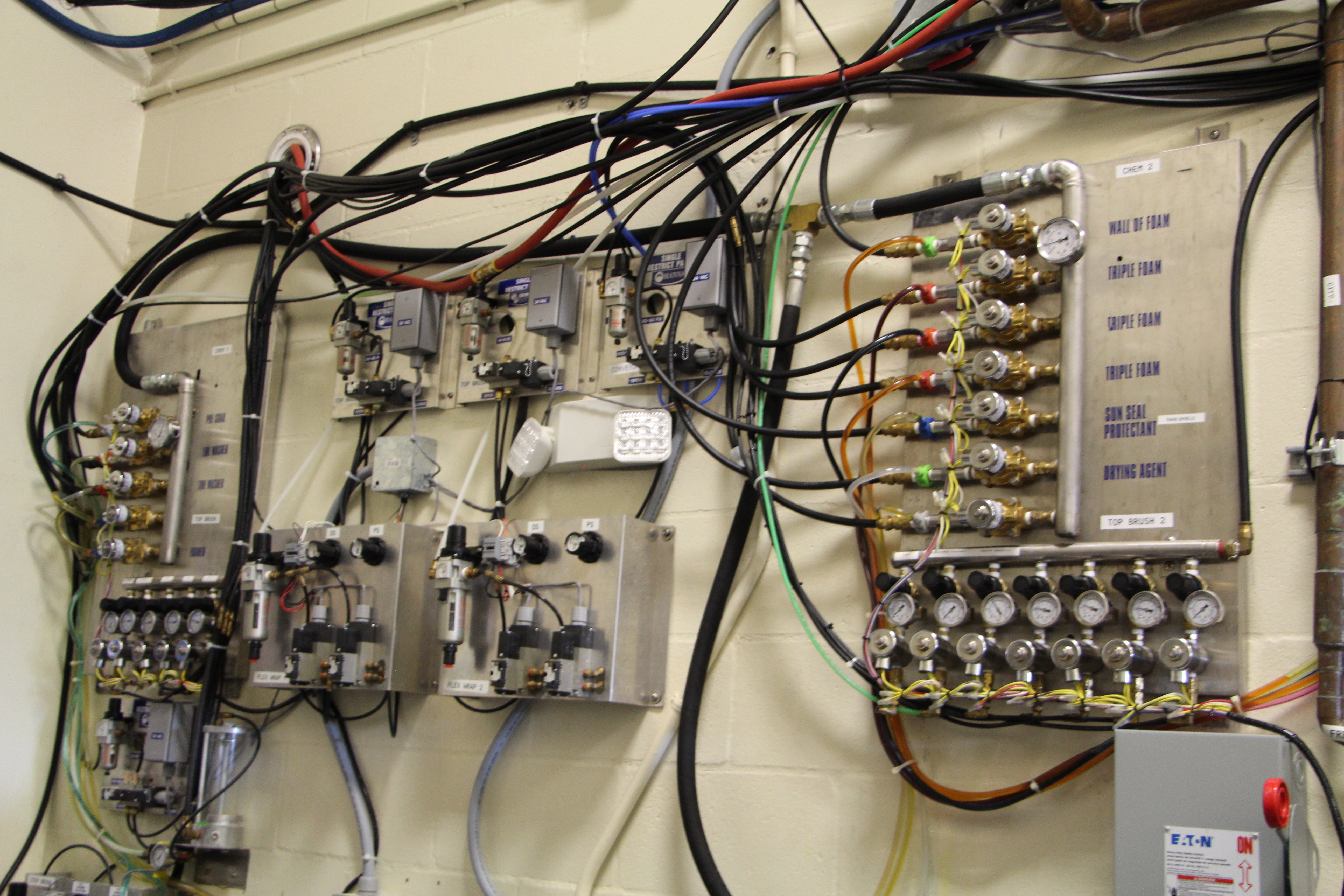

Today’s systems include a water pump to deliver the necessary consistent water pressure to the injection valve. The injector valve has an orifice that allows a predetermined number of gallons of water to flow thru it per minute. The injector then has an injector stem in which the chemical is sucked and mixed with the water. The amount of product mixed with the water is determined by the size of the opening in the tip. The stems have changeable tips to control the mixture of the chemical.

The nozzles that deliver the product to the system have to be correctly sized so as to not create any back pressure against the injector. Any back pressure stops the suction of the chemical. Once the relationship between the flow of the orifice and the nozzle is understood the design and implementation are easy to understand.

Since the chemical delivery system is critical to the operation of the car wash it is recommended to have a spare pump with quick disconnect fittings for easy change over in the event of a pump failure on the DSI system. Each function is controlled by a solenoid turned on and off by the site controller.