Tunnel Support Equipment

Each tunnel system requires necessary tunnel support equipment. At Coleman Hanna we offer all the equipment room and entry systems you will need: Air Compressors, Air Coolers, Tunnel Controllers, Motor Control Centers, Entry Systems & Cash Management, and Hydraulic Power Packs.

Air Compressors / Air Coolers

Fully packaged with after cooler, vibration isolators, automatic tank drain and pre-mounted motor starters

- 80 gallon vertical tank with NEMA ODP motor

- Complies with ASME code requirements

- 80/20 duty rated

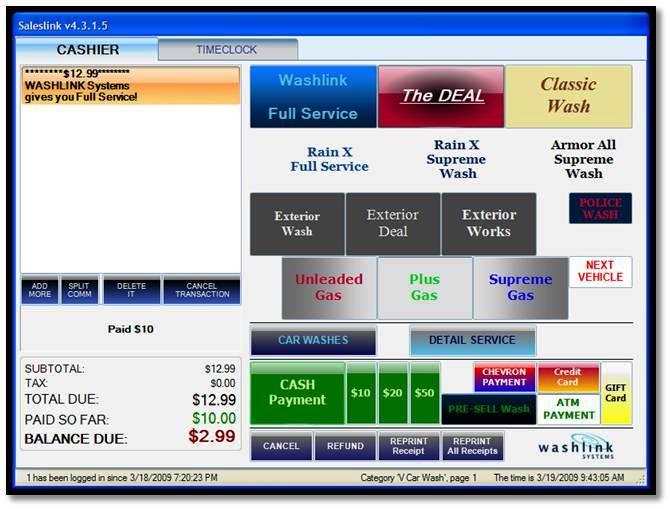

Hanna Systems SalesLink POS Cash Management

The point-of-sale management information system is a full feature PC-based programmable sales management system and cash register which seamlessly integrates with the Hanna System Controls equipment controller to provide superior cash accountability and employee management control.

Features & Benefits:

- Large 15” touch screen with unprecedented functionality, durability, quality and affordability

- Heavy duty cash drawer

- High speed thermal receipt printer

- Biometric (finger print) login for maximum security

- Integrated card reader and barcode scanner for credit, debit and gift/loyalty cards

- Fully integrates with Hanna System Controls equipment controller, but functionally independent – sales terminal with never shut down car wash tunnel operation

- All standard reporting including cars/man hour, labor $ and %, etc.

- Suggestive selling on all packages to promote up-selling by employees.

- Module for gift/loyalty/fleet/unlimited provides high powered sales tool

- Module for high speed credit car clearing can be used with customer’s bank of choice

- Wireless handheld sales terminal accepts credit cards and prints receipts remotely

- Multiple cash drawer and multiple terminal support for maximum cash control and flexibility

- Hanna system equipment controller interface built in

- Customizable reports will export to user spreadsheet programs such as Excel or QuickBooks

- E-mail/text messaging provides on-the-go reports and alerts

- Remote access to all screens from any computer with internet access

- Multi site replication between all stores and office or home

- Uninterruptible power supply for maximum protection

System Includes:

- 15” Touch Screen Terminal

- Cash Drawer

- Dell PC with report printer

- Three Line Car Reader

- Barcode Scanner

- Biometric (fingerprint) Login

- Uninterruptible Power Supply

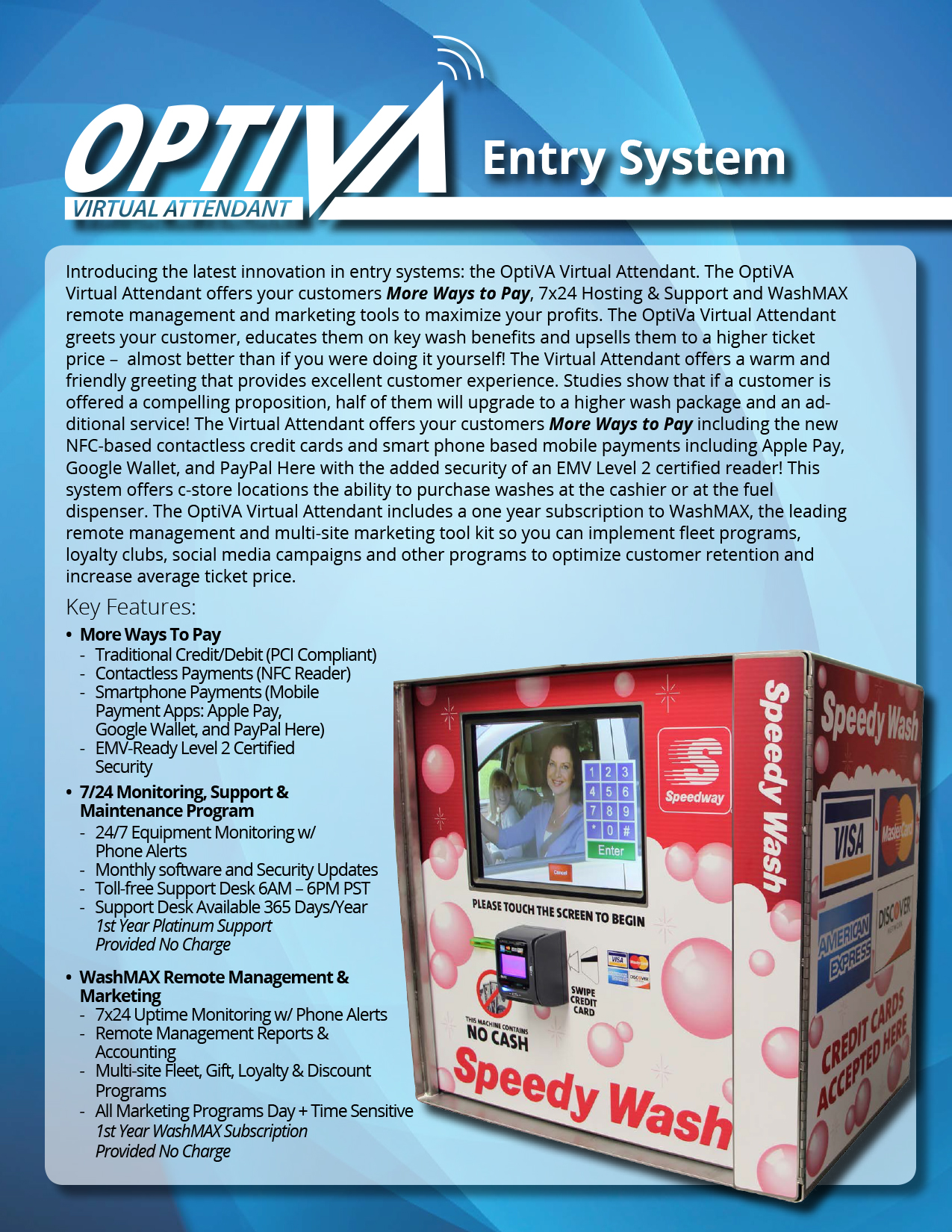

Optiva Virtual Attendant Entry System

Introducing the latest innovation in entry systems: the OptiVA Virtual Attendant. The OptiVA Virtual Attendant offers your customers More Ways to Pay, 7x24 Hosting & Support and WashMAX remote management and marketing tools to maximize your profits. The OptiVa Virtual Attendant greets your customer, educates them on key wash benefits and upsells them to a higher ticket price – almost better than if you were doing it yourself! The Virtual Attendant offers a warm and friendly greeting that provides excellent customer experience. Studies show that if a customer is offered a compelling proposition, half of them will upgrade to a higher wash package and an additional service! The Virtual Attendant offers your customers More Ways to Pay including the new NFC-based contactless credit cards and smart phone based mobile payments including Apple Pay, Google Wallet, and PayPal Here with the added security of an EMV Level 2 certified reader! This system offers c-store locations the ability to purchase washes at the cashier or at the fuel dispenser. The OptiVA Virtual Attendant includes a one year subscription to WashMAX, the leading remote management and multi-site marketing tool kit so you can implement fleet programs, loyalty clubs, social media campaigns and other programs to optimize customer retention and increase average ticket price.

More Ways To Pay

- Traditional Credit/Debit (PCI Compliant)

- Contactless Payments (NFC Reader)

- Smartphone Payments (Mobile Payment Apps: Apple Pay, Google Wallet, and PayPal Here)

- EMV-Ready Level 2 Certified Security

24/7 Monitoring, Support & Maintenance Program

- 24/7 Equipment Monitoring w/ Phone Alerts

- Monthly software and Security Updates

- Toll-free Support Desk 6AM – 6PM PST

- Support Desk Available 365 Days/Year

- 1st Year Platinum Support

- Provided No Charge

WashMAX Remote Management & Marketing

- 24/7 Uptime Monitoring w/ Phone Alerts

- Remote Management Reports & Accounting

- Multi-site Fleet, Gift, Loyalty & Discount Programs

- All Marketing Programs Day + Time Sensitive 1st Year WashMAX Subscription Provided No Charge

- Windows Embedded POS Ready 2009

- 15” multi-touch regradable touch screen from 3M

- 1500nit LED backlit transective display

- Custom wrap to augment your site branding

- 100% Stainless Steel Enclosure

- Secure EMV Lvl 2 Credit/Debit Card Processing

- POS Interface for code sales at Pump & inside Store

- High speed thermal printer with programmable receipt messages

- ContactLess Near Field Communication Receiver

- 3 outdoor-rated 10W speakers for stereo sound/intercom

- 100 BaseT Ethernet port with lightening suppression

- 3rd Party Certified PCI Compliant credit and gift card acceptance

- Post sale advertisement (“Escrow Video”)

- Wash menu function to show what each wash includes

- Optioning sales feature allows for the sale of up to two Extra Services

- Locking System with optional security alarm

- Industry-leading customer loyalty programs

- Multi-site fleet account programs

- Remote Uptime Management monitor with error code notification through text or email message

- Discount Codes—scheduled promotions that discount one or more wash packages by time of day or day of year.

- RFID Reader for monthly and annual WashPass © programs.

- Loss Traffic Control System - Express Tunnel Automation

- Gate Controller with interfaces to most tunnel controllers

Optiva Virtual Attendant Entry System Brochure

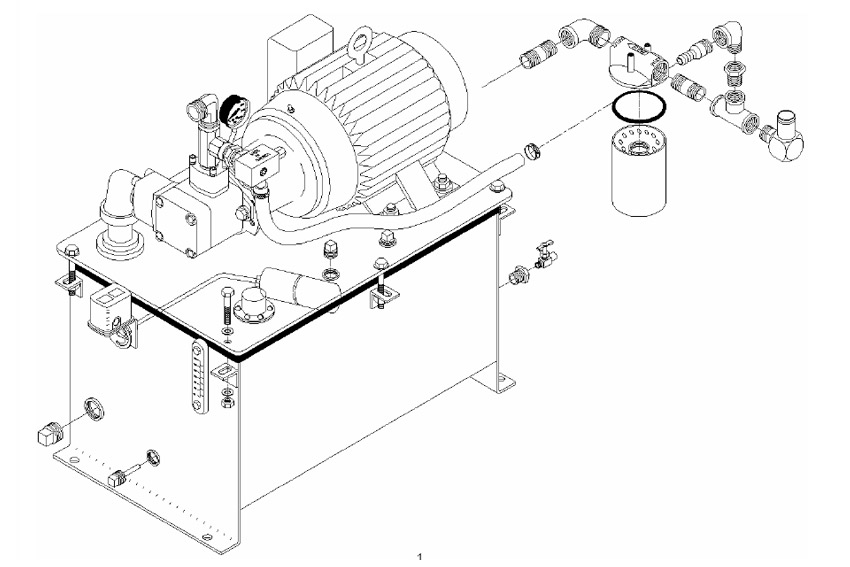

Hydraulic Power Packs

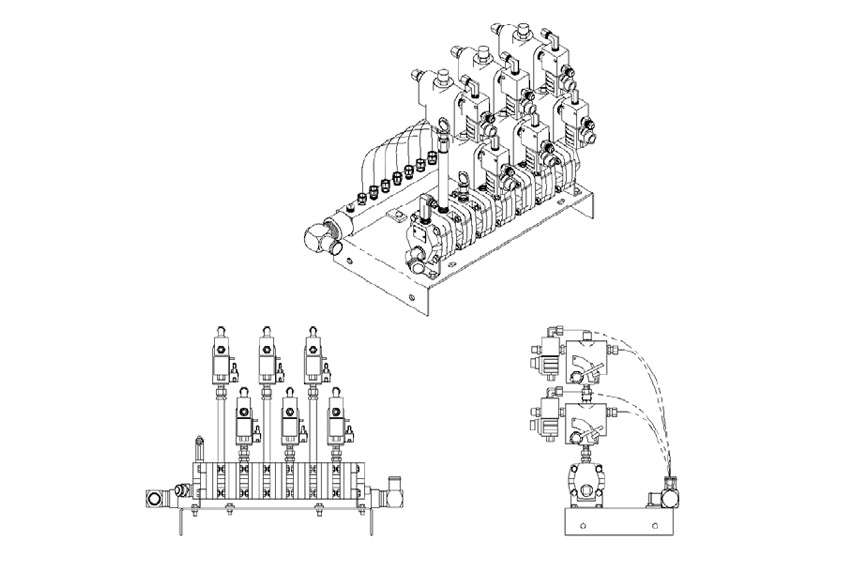

Proportionators

- Proportionators are available from 2 to a maximum of 7 banks.

- The priority valve has an internal relief system for control of flow and pressure to ensure optimal control of the car wash.

- This will allow the PLC to turn on the hydraulics, as the component is needed during the wash process.

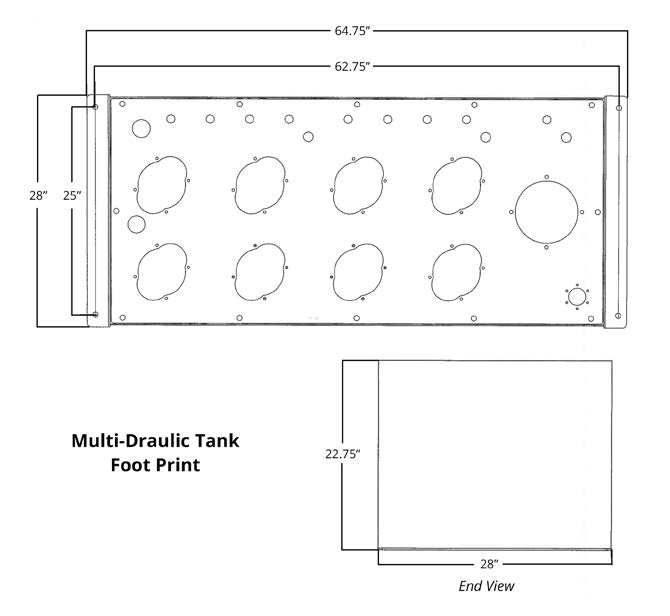

- Dimensions: 64.75” W x 28” D x 22.75” T

- Stainless Steel 80 gallon Hydraulic Tank with up to 7 motors & pumps mounted on top.

- The Base system comes with tank, one conveyor pump and motor, return filter, float switch, and filler cap.

- Tailor the base system to fit your needs by adding more pumps and motors.

- Energy efficient - Only motor that runs is forthe actual Hydraulic need in the conveyor

3 Motor Types to run different components:

- 1.5 KW Motor - HSS, HFT, S20 Mitters and Water Wizard Arch

- 2.2 KW Motor - Set of Flex Wraps, Side Brushes, Top Brush, Rocker Panel Brush, Tire Washer, or Tire Glaze

- 3 KW 4 HP Motor - Conveyor

Multi-Draulic Unit

Brushes

| Component | Gallons Per Minute | Code |

|---|---|---|

| Angled Side Window Washer | 3 GPM | D304 |

| Focus Flex Wrap | 6 GPM | 307 |

| Dual Pack Flex Wrap | 6 GPM (per set of brushes) |

307 + 307 |

| Grill Washer | 3 GPM | 304 |

| Hub Cap Rocker Panel | 3 GPM | 304 |

| Rotary Top Brush | 6 GPM | 307 |

| Side Horizontal Window Washer | 3 GPM | 304 |

| Stack-n-Scrub Flex Wrap | 6 GPM (per set of brushes) |

307+307 |

| Stepped Brush | 6 GPM | 307 |

| Tire Washer | 6 GPM | 307 |

| Tire Glaze | 3 GPM | 304 |

| 98 C | 6 GPM | 307 |

Mitters

| Component | Gallons Per Minute | Code |

|---|---|---|

| Diagonal Touch Mitter | 3 GPM | 304 |

| Finishing Touch Mitter | 3 GPM | 304 |

| HSS-2 Mitter | 3 GPM | 304 |

| S-20 Mitter | 3 GPM | 304 |

High Pressure

| Component | Gallons Per Minute | Code |

|---|---|---|

| Auto Prep | 3 GPM | 304 |

| Water Wizard Arch | 3 GPM | 304 |

RCV Conveyor

| Component | Gallons Per Minute | Code |

|---|---|---|

| RCV Conveyor | 9 GPM | 310 |

Motor Control Centers (MCC's)

Our MCC’s are designed to start and protect the electric motors in HCW Wash Systems and provide branch circuit protection required by the National Electric Code and other international electrical safety standards.

Standard Features:

- UL / CE listed panels ( additional charge for CE listed panels)

- Thru-door disconnect

- Industrial Nema 12 enclosure

- Control power kill switch stops all wash functions

- Labeled Hand, Off, Auto (HOA) switches for each motor

- Electrical schematic on panel door and in print form

- Standard, name brand, industrial components

- Individual lock off provision for all motors

- Cooling fans included on most cabinets

- Time delay relays included to "stagger start" up to eight motors

- Available as Standard Start (X-Line), Soft Start or VFD controlled starters.

- All MCC’s are manufactured as top feed for power unless otherwise specified in writing at time of placing order

- Customer is responsible for any additional cost resulting from power company special requirements such as locked rotor amps.

- Please state any special code requirements for your area, as any additional modification will be charged to distributor/customer.

- Systems must be tested for correct FLA on motor and voltages to validate the warranty of the electrical panels and motors returned to HCW.

Optional Features:

- Circuit breakers

- Embedded PLC to connect to V4 Controller

- Thru-Door Touch Screen to monitor MCC performance

- Variable Frequency Drive for motors

Hanna Carwash Systems features a quality brand Controller which is a PLC based tunnel controller that coordinates and controls all conveyor and wash equipment.

The controllers are also available to upgrade older or competitive systems in both a controller as well as a controller package for a system.

- Conveyor and roller Control

- Programmable and sequential functions with mode select

- Functions interlocked with conveyor stop and optionally with roller fork

- Dryer look ahead

- Function counters

- Unattended control and car stacking

- Controller includes enclosure, override switches, 15amp isolation relays, PLC and fusing.

- Control of conveyor and roller raiser is included. No separate Auto Start/Stop or Roller Raiser Control is necessary.

- Inputs are included for start (4), stop (4), hydraulic low level (2), collision (2), packages (16), options (5), tire switch, wet down, extra roller, clear, pulse and roller detect.

- Outputs are included for horn, roller raiser, conveyor run.

- Available in 120V-60Hz or 220V-50Hz.

- All Adjustments can be done on PC or entrance touch screen

- Fault for loss of pulse, enter, tire switch, low level, wet down, mode change and more

- Built in Stacker and Auto roller control

- Easily handles 20 packages and 15 options

- UL / cUL listed panels

- Extremely reliable with MTBF rates that exceed most PC computer failure rates.

- Industrial PLC with an Industrial grade noise suppressing power supply.

- Non-Proprietary—standard components available worldwide.

- Water tight/corrosion-resistant enclosures.Override switches for all functions.

- Provided for manual control and diagnostic capability.

- Small MMI interface panel provides reliable programming without providing accidental access to the program code.

- Wash options may be sold as a program group or by individually selected options.

- Equipment Controller in Non Metallic Nema 4 Enclosure.

- 6" Touch Screen for Tunnel Entrance w/Stainless Steel Enclosure

- 140' Communication Cable to connect Touch Screen to Equipment Controller

- Licensed Director PC, Flat Screen Monitor, Report Printer, Biometric Keyboard and Mouse

- Cat 5 cable from Director PC location to Equipment Controller

- Broadband Internet Connection for remote access, alerts etc. (Optional but Highly Recommended)

- Input Devices. i.e. Pulse, Enter, Roller Detect, Collision Avoidance, Start Stop Stations, etc.

- 24vac Low Voltage Transformer (750va recommended)

Vacuum Systems

Single Vacuum

performance quality you expect from Coleman Hanna. Our most popular vacuum, provides

dependable service with low maintenance required. This unit does not come standard with graphic decals but custom decals are optional. This unit also does not come standard with

digital timers.

Standard Features:

- 18 gauge stainless steel body

- Fuse protected

- 2” vacuum hose and cuff

- Solid state 110V adjustable timer

- Test switch

- 2 - 1.6 H.P. vacuum motors

- Dual latch clean out door

- Your choice of dome color

- Choice of Switch, Push Button, or Coin Acceptor Model.

- Optional: standard or custom graphic decals; pole or pedestal mount

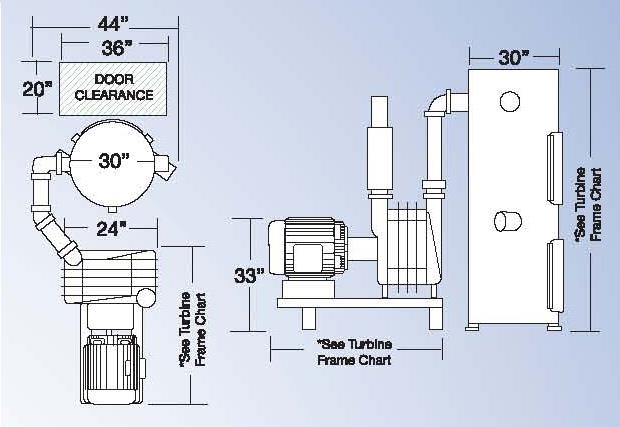

Central Vacuum System

Easily provide multiple vacuum stations with one central system with the Coleman Hanna Central Vacuum System. This central vacuum system provides ease of use with only one central location to service. The central vacuum system is ideal for locations with free vacuums such as full service and express tunnels. Our improved producer has larger bearings with an optional 25 HP model. Likewise, an optional vacuum gauge can be mounted on the collector to monitor the performance of the system. Lastly, the attractive and long-lasting stainless steel vacuum arches are sure to entice customers to stop.

- NEW Hanna Central Vacuum has been improved to provide longer life and better performance.

- Comes with an exhaust pipe to easily install a muffler if needed or desired

- Heavy Duty Bearings and 1-1/4” shaft, larger than the old design

- Optional vacuum gauge can be mounted inside the collector to measure the performance of the vacuum

- Dimensions mounted producer and collector 28”x100” ( 0,72 m x 2,55 m )

- Durable Stainless Steel Parts

- 20 HP or 25 HP model available

- Hanna Vacuum Gauge mounted inside collector

- Hanna Stainless Steel Muffler

- Hanna SS top to go on top of Muffler for outside service

- Hanna Stainless Steel Square Vac Collector

| Hanna 25 HP Central Vacuum with Collector |

(8-10 users) |

| Hanna 20 HP Central Vacuum with Collector |

(6-7 users) |

| Hanna 15 HP Central Vacuum with Collector |

(5-6 users) |

-

- Stainless Steel arches that can be linked together with a cover to provide shade for your customers

- Post is 6" x 6" x 10 tall

- Arches are availble in carbon steel with paint

- Arches can be ordered with Powder coating.

- Shade cloth can be ordered in standard colors such as blue, green, red, black, and yellow.

- Dual or Single Arch Arms

- Optional: Stainless Steel Trash Can mounted to Pole, Lights

-

-

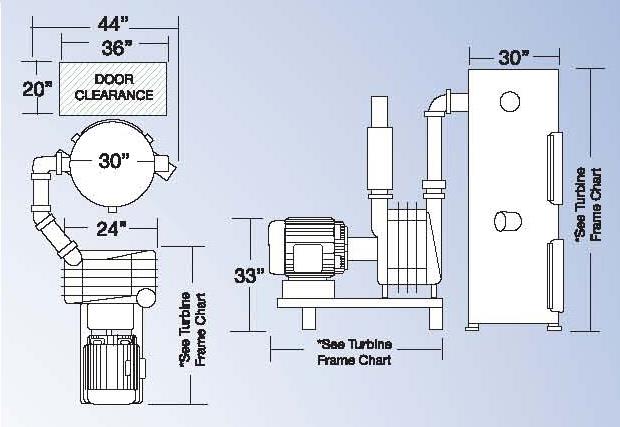

- Central Vacuum Systems are designed for altitude below 3000' for maximum performance.

- Available in standard 3 phase, 208/230/460 voltage at 60 hertz

- Industrial duty vacuum producer with 3, 4, 5, 6 or 7 Stage Impeller

- Hardware packages include 3 vibration pads and 2 Pipe Isolator Connectors (No-hub Coupling)

-

| Total Simultaneous Users 15’ x 1 ½” Dia. Vac Hose | HP | Vacuum Frame Dimensions | Weight lbs. | Decibels at 10 ft. | Separator Dimensions | Order # |

| 3–4 Users | 10 HP 3600 RPM |

38” | 850 | 70 | 64” x 30” | 426700 |

| 4–5 Users | 15 HP 3600 RPM |

48” | 975 | 71 | 64” x 30” | 426705 |

| 5–6 Users | 20 HP 3600 RPM |

48” | 1050 | 72 | 76” x 30” | 426710 |

| 6–7 Users | 25 HP 3600 RPM |

54” | 1200 | 74 | 76” x 30” | 426715 |

| 8–10 Users | 25 HP 3600 RPM |

60” | 1250 | 72 | 76” x 30” | 426720 |

| 10–12 Users | 30 HP 3600 RPM |

64” | 1300 | 74 | 76” x 30” | 426725 |

-

-

- Central Vacuum Systems are designed for altitude below 3000' for maximum performance.

- Available in standard 3 phase, 208/230/460 voltage at 60 hertz

- Industrial duty vacuum producer with 3, 4, 5, 6 or 7 Stage Impeller

- Hardware packages include 3 vibration pads and 2 Pipe Isolator Connectors (No-hub Coupling)

-

| Total Simultaneous Users 15’ x 1 ½” Dia. (4.572 m x 3.81 cm Dia.) Vac Hose | HP | Vacuum Frame Dimensions | Weight lbs. | Decibels at 10 ft. (3.01m) | Separator Dimensions | Order # |

| 3–4 Users | 10 HP 3600 RPM |

38” (96.52 cm) | 850 | 70 | 64” x 30” (162.56 cm x 76.2 cm) | 426702 |

| 4–5 Users | 15 HP 3600 RPM |

48” (121.92 cm) | 975 | 71 | 64” x 30” (162.56 cm x 76.2 cm) | 426707 |

| 5–6 Users | 20 HP 3600 RPM |

48” (121.92 cm) | 1050 | 72 | 76” x 30” (193.04 cm x 76.2 cm) | 426712 |

| 6–7 Users | 25 HP 3600 RPM |

54” (137.16 cm) | 1200 | 74 | 76” x 30” (193.04 cm x 76.2 cm) | 426715 |

| 8–10 Users | 25 HP 3600 RPM |

60” (152.4 cm) | 1250 | 72 | 76” x 30” (193.04 cm x 76.2 cm) | 426720 |

| 10–12 Users | 30 HP 3600 RPM |

64” (162.56 cm) | 1300 | 74 | 76” x 30” (193.04 cm x 76.2 cm) | 426725 |

-

-

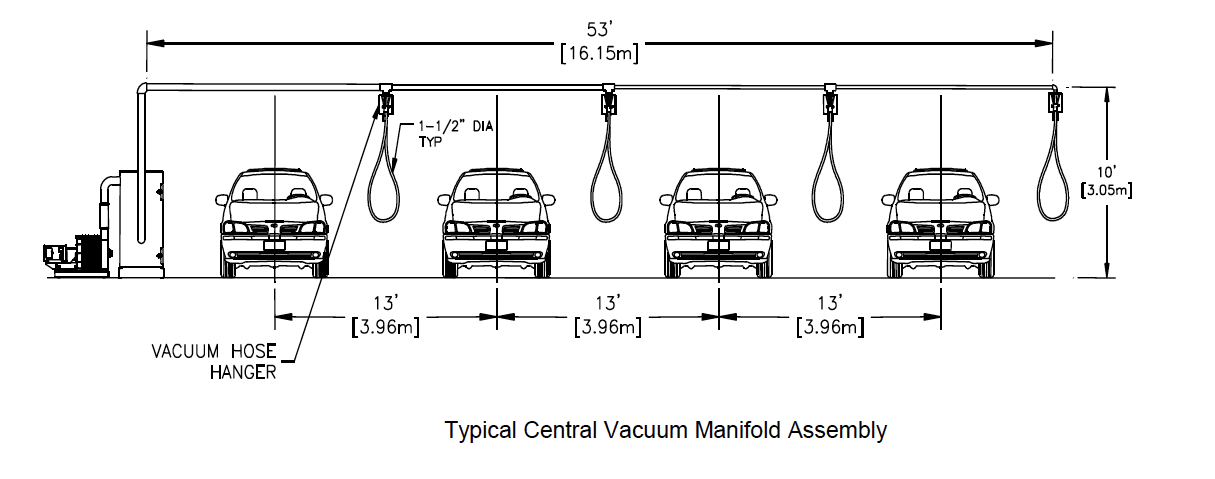

- Each installation of PVC manifolds for the Central Vacuum varies

- Contact order processing for any additional piping that may be required.

- Please consult order processing for special on site vacuum manifold layout.

- Please notify order processing at time of order.

- Please consult order processing for manifolds that exceed 8 drops to ensure the correct producer has been selected for airflow velocity.

-