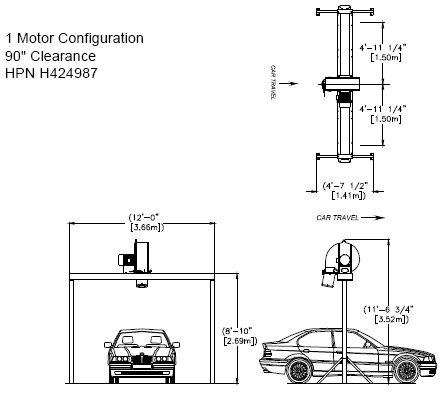

Drying & Polishing Equipment

Finish your conveyor tunnel with durable and reliable Drying & Polishing Components. For drying equipment, Coleman Hanna offers a wide selection including the H.E.S.S. (High Efficiency Stainless Steel) Dryers, EQ Dryers, Fin Dryer Attachment, and the Wind Blade.

Add a finishing shine with the latest Gleam Machine, which dries and buffs the vehicle providing the customer with an added service. The Gleam Machine provides an extra revenue generating service that entices customers to purchase higher wash packages.