Water Treatment, Reverse Osmosis & Water Softeners

From the high efficiency Sweetwater Reclaim Water Treatment System to the Reverse Osmosis Spot-Free Rinse to the Water Softeners, Coleman Hanna offers all the latest advances in water treatment and reprocessing. Saving water is crucial in today's world. Modern car washes require water reclaim or recycling systems to decrease the amount of fresh water usage. Spot-Free Reverse Osmosis Systems are vital to ensure a spot-free final rinse to the vehicle. Water Softeners have always been essential to remove hardness in the water and prepare it for car washing.

Sweetwater Water Treatment (Reclaim) System

ozone removes color and odor and the optional bio control gets rid of surfactants, keeping your storage tank water fresh. Slim design fits easily into most equipment rooms or wash bays.

- Centrifugal Pump

- Oversized Basket Strainer

- Foot Valve & Strainer

- VFD to change the speed of the pump for variable output on the pump

- Cyclone separator has 16 small cyclone separators in one housing for peak performance

- Automatic bypass with pressure switch

- PLC mounted inside Nema Enclosure with interface to display errors and conditions of equipment

3 phase 208-240/460 volt ac

Ozone

Bio Control- Programmed Bio Pump with Munox Injector

Stainless Steel Bag Filter

Self Cleaning Filter

Filtration System

- Height: 77”, Width: 62.25”, Depth: 21” weight 615 lb (shipping weight 740 lb)

- Input power: 208/230/480 volt, 3 phase @ 13.1 / 11.5 / 5.7 amp max (50 or 60 hz)

- Control Power: 115 vac, 60 hz 2 amp max, or 230 vac 50 hz 1 amp max

- Automatic Control: On/OFF/Automatic push button control with display screen

- Automatic Fresh Water Bypass capable of 10 amp max output energizes on low pressure

- Primary Pump: 5 HP pump, 120 GPM @ 65 max PSI

- Particulate Separator: 16 or 32 Self-Purging Vortex Filters with clear Lexan bowl

- Inlet filtration: Oversized Stainless Steel Cleanable Basket Strainer lint filter

- Primary Filtration: single or dual element cyclonic separators with filtration down to 10 micron

- Water Inlet: 3” FNPT

- Filtered Water Outlet: 2” FNPT

- Purge Outlet: 1 ½” FNPT

- Self Cleaning Cycle Time: 7 seconds

- Recirculation via 1” FNPT preset pressure regulator to ozone or air sparging manifold

Ozone/Bio Control

- Ozone or oxygen injection manifold size 1”, included.

- Plumbing line size 1.25” required

- U.L. approved electronics provide world wide service.

- Self cleaning dirt collection and extra large pre-filter reduces maintenance saving time and money.

| Model | HP | GPM | Cyclones | Can be Used for: |

|---|---|---|---|---|

| Base Model 16CS60-3 | 3 | 60 | 16 |

|

| Model 16CS100-5 | 5 | 100 | 16 |

|

| Model 32CS100-5 | 5 | 120 | 32 |

|

- Hose connections ok to hook-up equipment to suction and discharge stub-ups. Use reinforced suction approved hose. Max suction= 30” HG vacuum

- Use SCH 80 PVC union with viton o-ring on ozone line. Spears Par # 8057-012

- Do not use copper for ozone or bio line.

- Reclaim water out to equipment normally tubbed to wall pipe and not shown.

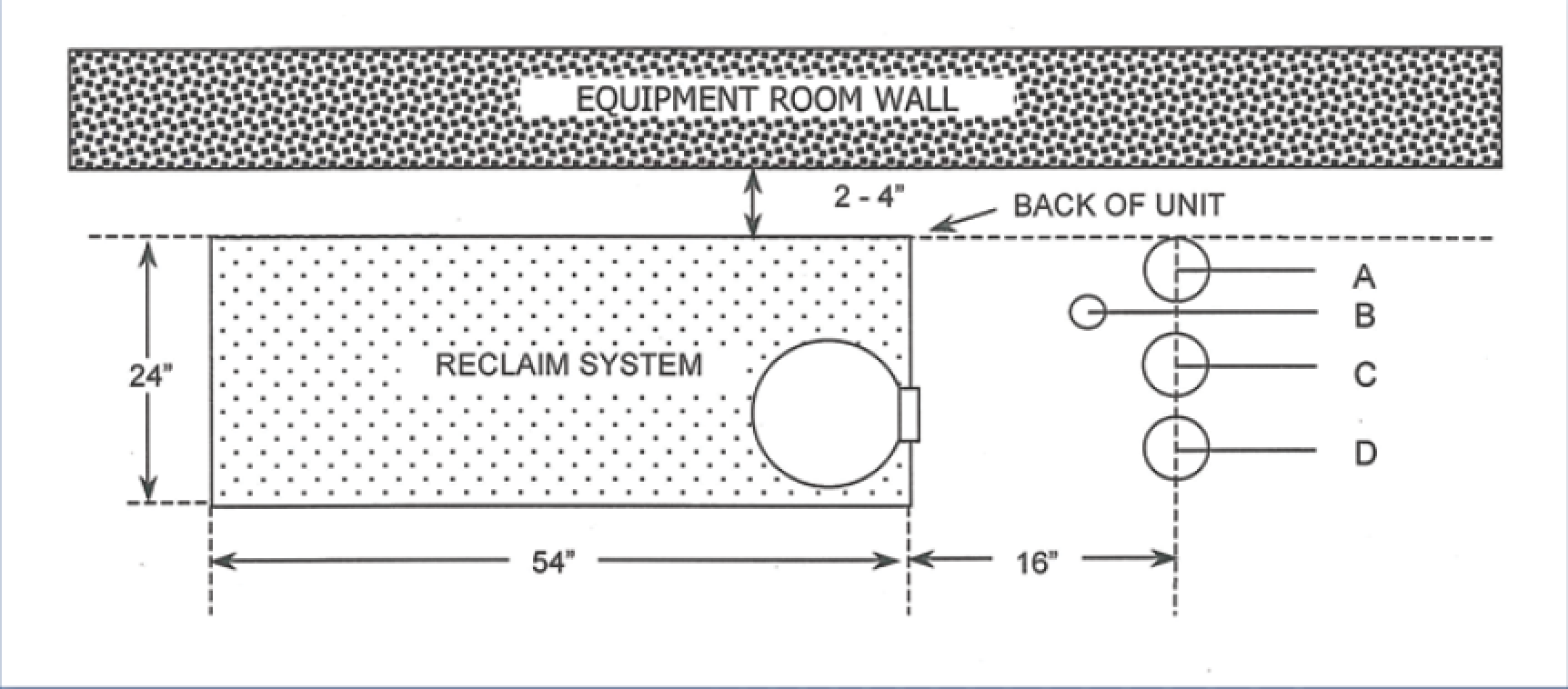

Dimensions from center of pipe:

- Discharge line 3” PVC SCH 40 or 80 2” from back of the unit

- Ozone or Bio line 1.25” PVC SCH 40 6” from back of the unit

- Suction Line 3” SCH 80 PVC 10” from back of the unit

- Spare Suction Line 3” SCH 80 PVC 14” from back of the unit

General Notes:

- Reclaim should sit two to four inches from equipment room wall.

- Do not stub-up pipes tight together or against wall.

- Leave room for plumbing to unit. We recommend 16”.

- Use SCH 80 cleaner and gray glue for suction lines. Cleaner and glue on all others.

- Use of 45 fittings instead of elbows on suction and discharge lines will improve performance.

Sweetwater Water Treatment/Reclaim Brochure

Sweetwater Spot Free Rinse System

Spot-free rinse is a very important part of the vehicle wash process. Water naturally contains Total Dissolved Solids (TDS), when water evaporates it leaves behind the solids or powders on the vehicle and they become spots.

What would have been a clean and shiny vehicle now is not and actually can lead to a displeased customer. This dissatisfied customer gives negative reviews about your business which prevents potential customers from visiting your car wash.

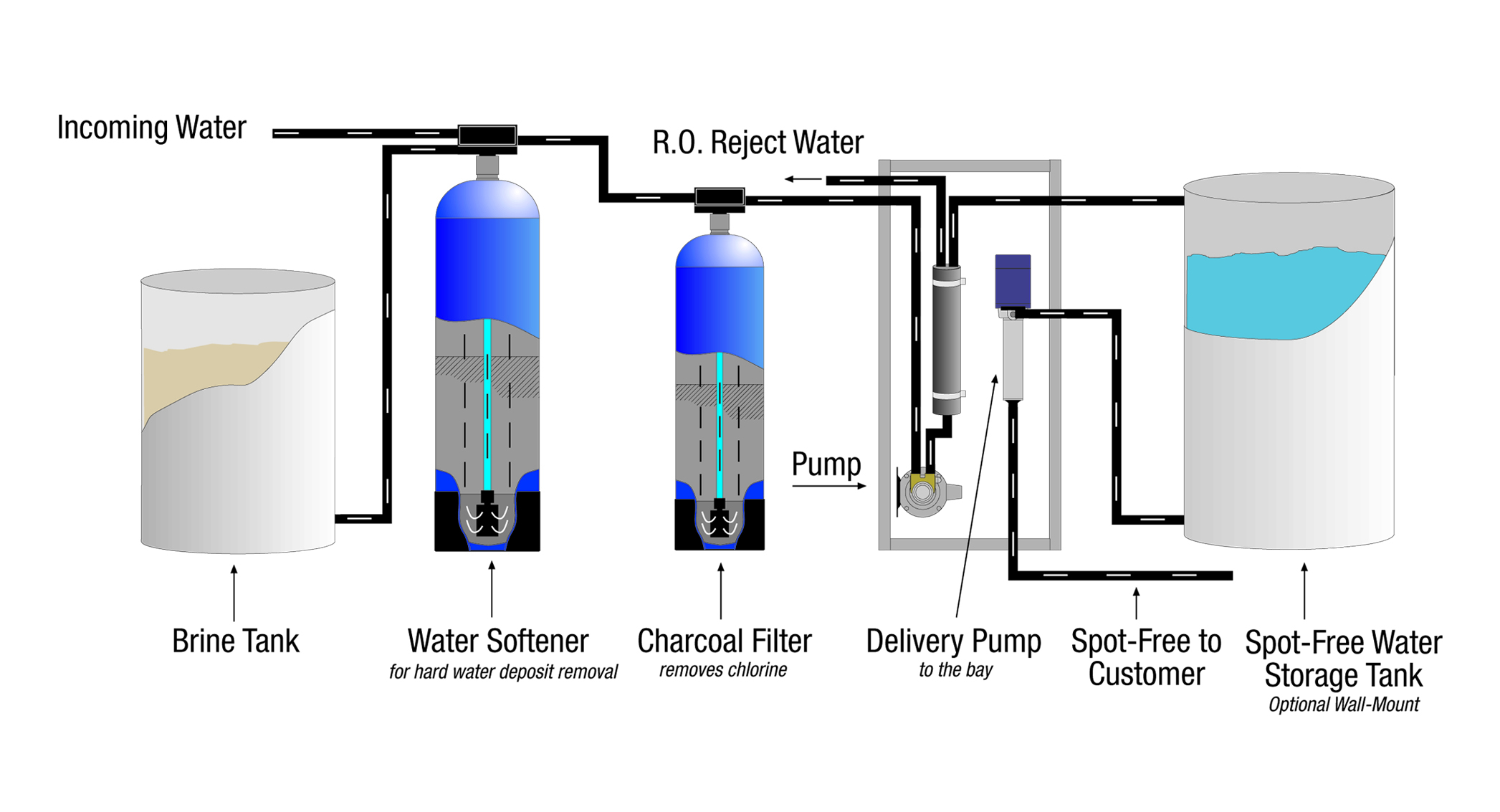

It is much easier and profitable to remove the spots from the final rinse water. Reverse osmosis is a mechanical process where fresh water, without chlorine, is pumped through membranes, which remove the TDS from the water. This produces clean water that allows vehicles to be rinsed and be spot-free. As the membranes collect the TDS they require a flushing process to keep them clean and functioning properly. This is called the reject water and can be designed to be recycled back into the system.

At Coleman Hanna we have learned that the most efficient way to size systems is to manufacture systems up to 6,000 GPD and then duplicate multiple systems into one to meet the daily requirement of the system. Water storage capacity is also a factor as water usage is usually in 10 hours per day or less while production is ongoing 24 hours per day

Reverse Osmosis Process

Engineering and Maintenance -

Engineered with the best available components on the market, the Sweetwater Spot- Free Rinse System will deliver low pressure pure water to the car wash bay. The Sweetwater Spot-Free Rinse System can be installed “on-board” for newly purchased wash systems or separately for existing car washes. Installation can usually be done in a day, without downtime. Regular maintenance can be done by the operator simply by changing prefilters and checking water for purity.

More Customers, More Profits -

By offering RO with your car wash, you will not only gain satisfied customers, but you can also increase your bay income. RO can produce up to 12% of your bay income. This is the most cost effective product in a bay giving you a high rate of return on

investment.

- Stainless Steel Frame

- 5 micro Prefilter

- Product Flow meters

- Reject Flow meters

- Reject Recover Flow meters

- Two production units on one frame to produce the product water

- Units available in 4,000; 6,000; 8,000; 10,000 or 12,000 GPD

- Computer controlled with automatic flush on membranes

- Two separate set of controls on one frame

- Delivery pumps available on the unit

- Includes a 5 or 6 cubic foot back washable Charcoal filter

- Three phase 208-230 volt or 460 volt

- Requires Three Phase Power

- 1 HP/3PH-14 Stage Booster Pump

- Motor Starter with 24V Coil

- Mounted on RO Production Stand

- Specify Voltage Signal to Turn on Delivery Pump if Different than 24V

- Hand-held

- Easy to Use and Read

- Sprite Brand

- 8” Manway Hole

- 3/4” Tank Adapter

- Weight: 50 Lb.

- Size: 31”D x 91”H

- 8” Manway Hole

- 3/4” Tank Adapter

- Weight: 120 Lb.

- Size: 46”D x 83”H

- This tank requires a 4 foot wide door

- 8” Manway Hole

- 3/4” Tank Adapter

- Weight: 165 Lb.

- Size: 46”D x 97”H

- This tank requires a 4 foot wide door

- 8” Manway Hole

- 3/4” Tank Adapter

- Weight: 180 Lb.

- Size: 48”D x 98”H

- This tank requires a 5 foot wide door

- 16” Manway Hole

- 3/4” Tank Adapter

- Weight: 230 Lb.

- Size: 60”D x 75”H

- This tank requires a 6 foot wide door

- 16” Manway Hole

- 1” Tank Adapter

- Size: 60”D x 100”H

- This tank requires a 6 foot wide door

- 500 gallon tank

- 20 GPM Re-Press pump

- Pressure Switch

- Float Control

- Bladder Tank

- Check Valve and Fittings

| Cars Per Day | Gallons Per Car | GPD | GPH | Recommended Size |

|---|---|---|---|---|

| 500 | 5 | 2,500 | 208 | 4,000 GPD 550 gallon tank |

| 600 | 5 | 3,000 | 250 | 4,000 GPD 1,100 gallon tanks |

| 700 | 5 | 3,500 | 292 | 6,000 GPD 550 gallon tank |

| 800 | 5 | 4,000 | 333 | 6,000 GPD 1,100 gallon tanks |

| 900 | 5 | 4,500 | 375 | 8,000 GPD 550 gallon tank |

| 1,000 | 5 | 5000 | 417 | 8,000 GPD 1,100 gallon tanks |

| 1,100 | 5 | 6,000 | 458 | 10,000 GPD 550 gallon tank |

| 1,200 | 5 | 7,000 | 500 | 10,000 GPD 1,100 gallon tank |

Sweetwater Spot-Free Rinse System Brochure

Water Recycling Systems

| 5 HP Pump | 130 GPM @ 45 PSI |

| 7.5 HP Pump | 150 GPM @ 60 PSI |

| 10 HP Pump | 150 GPM @ 80 PSI |

| 15 HP Pump | 180 GPM @ 100 PSI |

| 20 HP Pump | 230 GPM @ 100 PSI |

International Water Recycling System

- These systems are for areas utilizing 50Hz power

- Includes centrifugal pump, barrel screen, foot valve & strainer, prime tank, hydracyclone,spring loaded bypass valve, dump gate valve

- Consult order processing for applications where the centrifugal pump is located more than 16 ft from the re-circulation pit

| 3 HP Pump | 75 GPM @ 40 PSI |

| 5 HP Pump | 105 GPM @ 45 PSI |

| 7.5 HP Pump | 125 GPM @ 60 PSI |

| 15 HP Pump | 180 GPM @ 100 PSI |

| 10 HP Pump | 125 GPM @ 80 PSI |

Pressure Activated Booster Systems

| 3 HP Booster Pump | 90 GPM @ 40 PSI |

| 5 HP Booster Pump | 130 GPM @ 45 PSI |

| 50 Hertz 3 HP Booster Pump | 75 GPM @ 40 PSI |

| 50 Hertz 5 HP Booster Pump | 105 GPM @ 45 PSI |

Water Softeners

The size of water softener required for your car wash depends on the size of the RO system.

| Softener Type | Features |

|---|---|

| 9F Twin Alternating Tank Water Softener |

|

| Single Tank Softener |

|

| On-Demand Water Softener |

|

| Twin Interlock Softener |

|

| Twin Tank Alternating (Stand-By) with Water Meter |

|

| Watts Antiscale Water Treatment System |

1” Pipe size on Filter tank |

Water Meter Ranges

| 3/4” Standard | 125 - 2,100 Gallons |

| 3/4” Extended | 625 - 10,500 Gallons |

| 1” Standard | 360 - 5,000 Gallons |

| >1” Extended | 1,800 - 25,000 Gallons |